Dusty DT-25: REEFSCAPE

Season Summary

Pinnacles Regional:

Rank 9th

Alliance 6 Captain

Reached Semi-Finals

Excellence in Engineering Award

Contra Costa Regional

Rank 15th

Alliance 4 Member

Reached Quarter-Finals

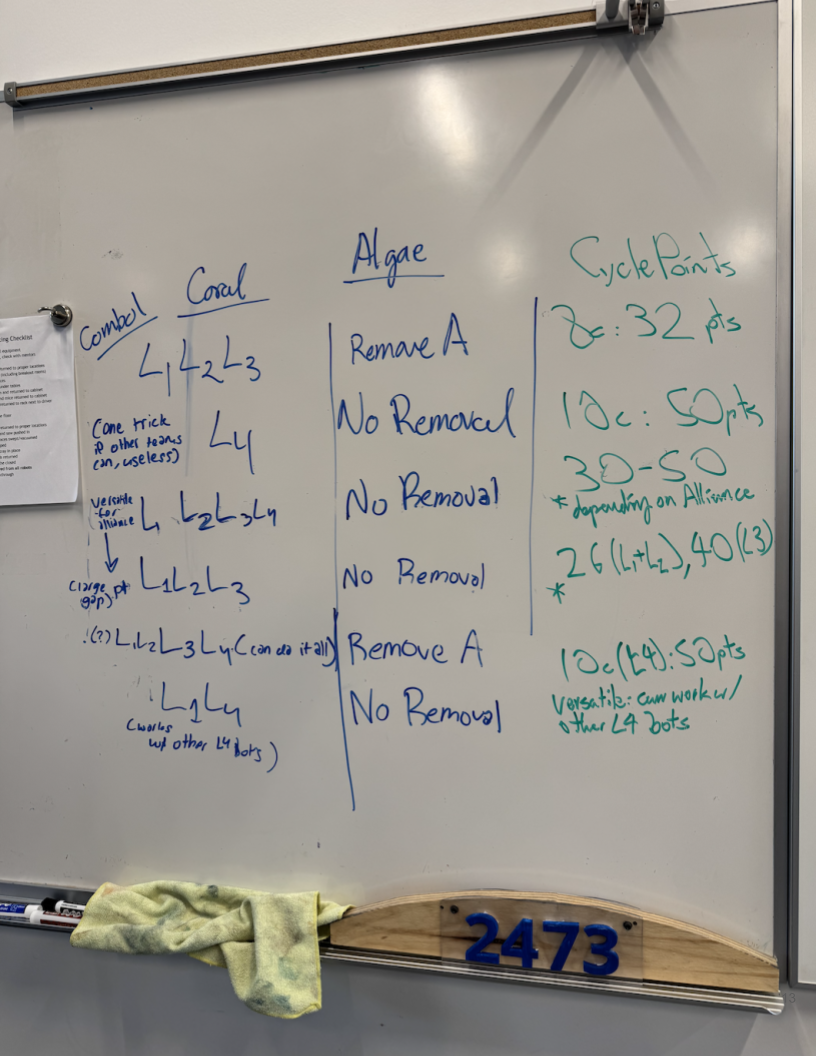

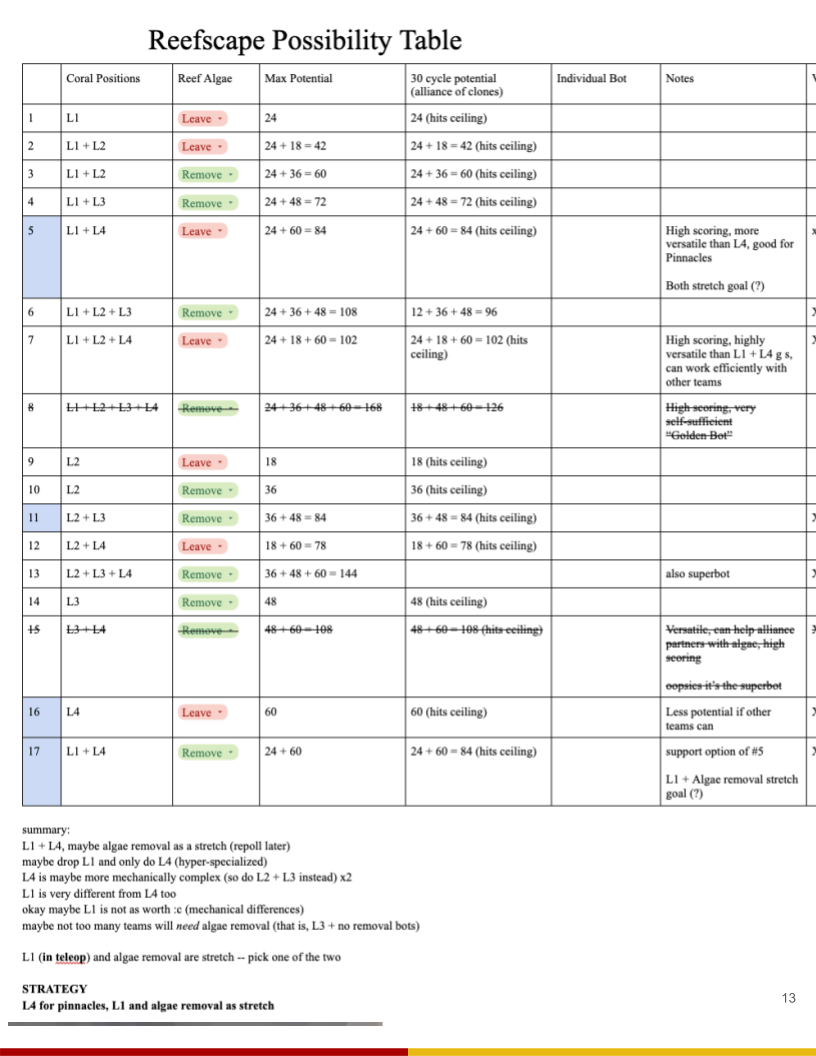

2025 Season Strategy

For the 2025 season, Team 2473 focused on disciplined strategy, consistency, and scalability, both in robot design and team structure. Our approach began on Kickoff with a full-team strategy-only discussion, intentionally separating game analysis from mechanism brainstorming. This allowed us to clearly define our priorities before committing engineering resources. We identified reliable autonomous scoring, fast and repeatable Tele-Op cycles, and a high-value endgame as the pillars of our competitive plan. After evaluating scoring tradeoffs, we committed to a robot specialized for efficient L4 coral cycles, prioritizing point density and consistency over lower-value game actions like algae interaction.

To execute this strategy effectively with a larger, four-year team, we emphasized structure and communication. We introduced Gantt-based scheduling to manage dependencies across subteams and held weekly cross-functional check-ins to surface risks early. This combination of clear strategic goals and strong project management enabled us to deliver complex systems on schedule while giving students ownership over both technical decisions and timelines.

Hardware (HW)

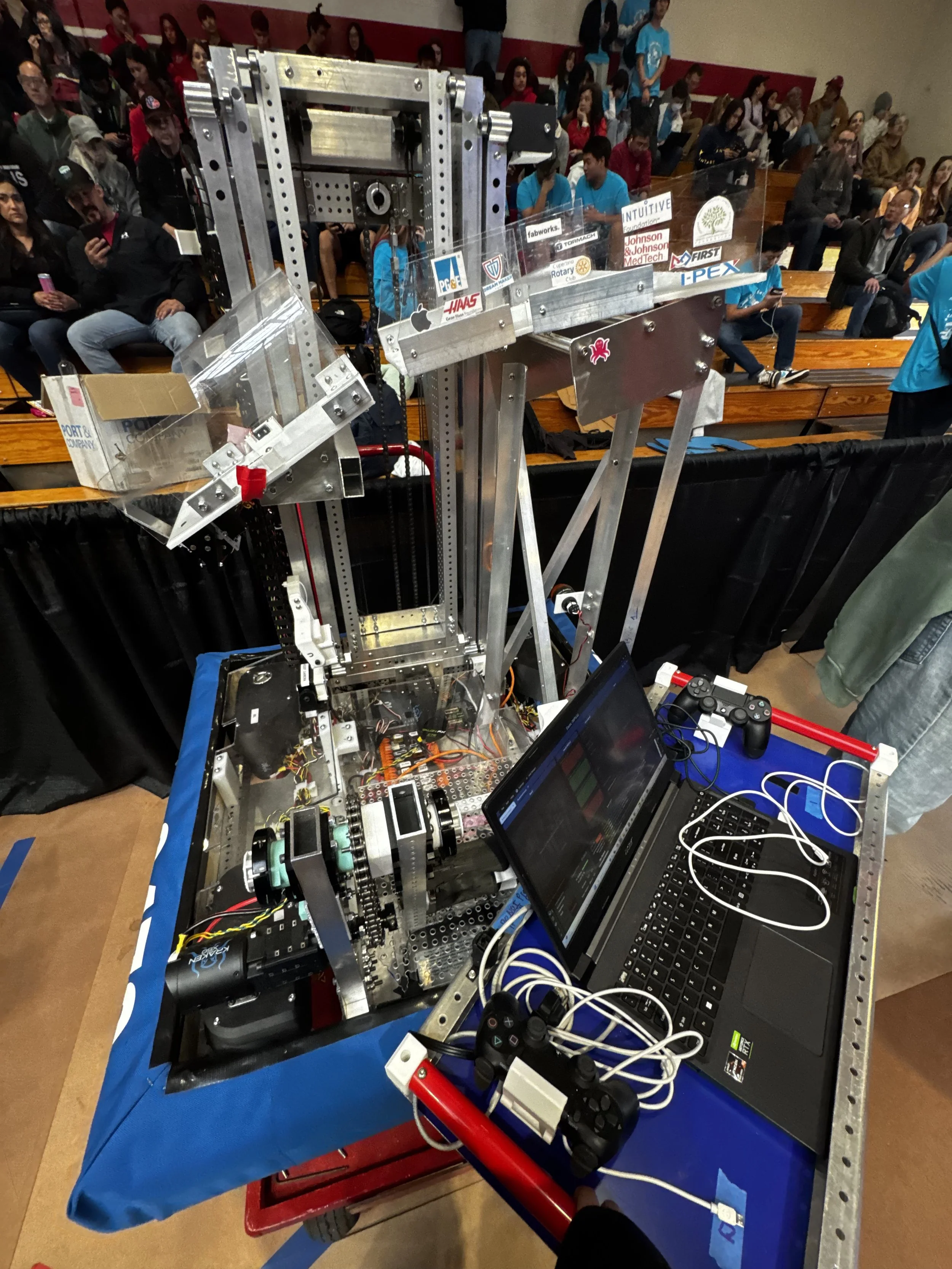

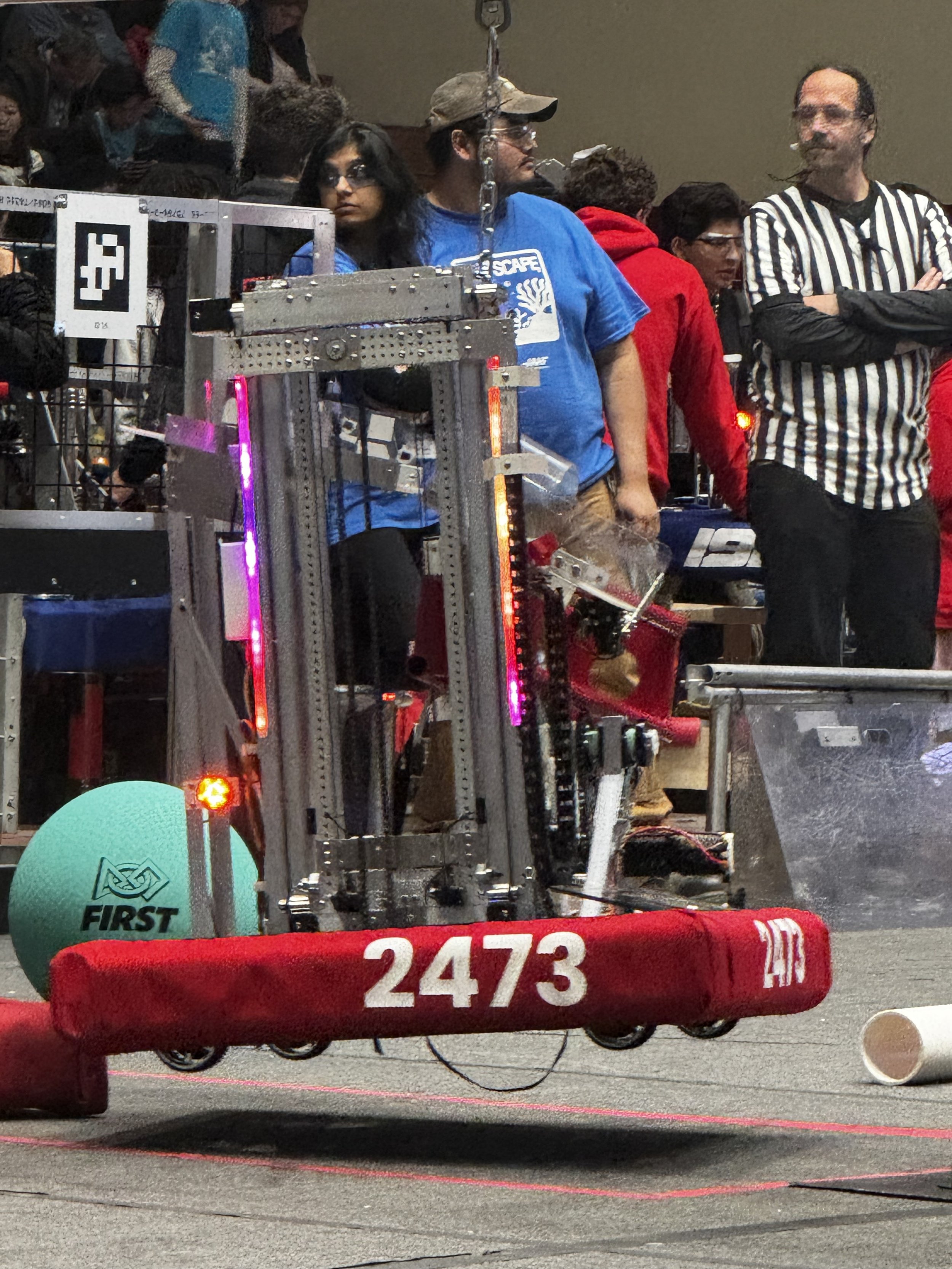

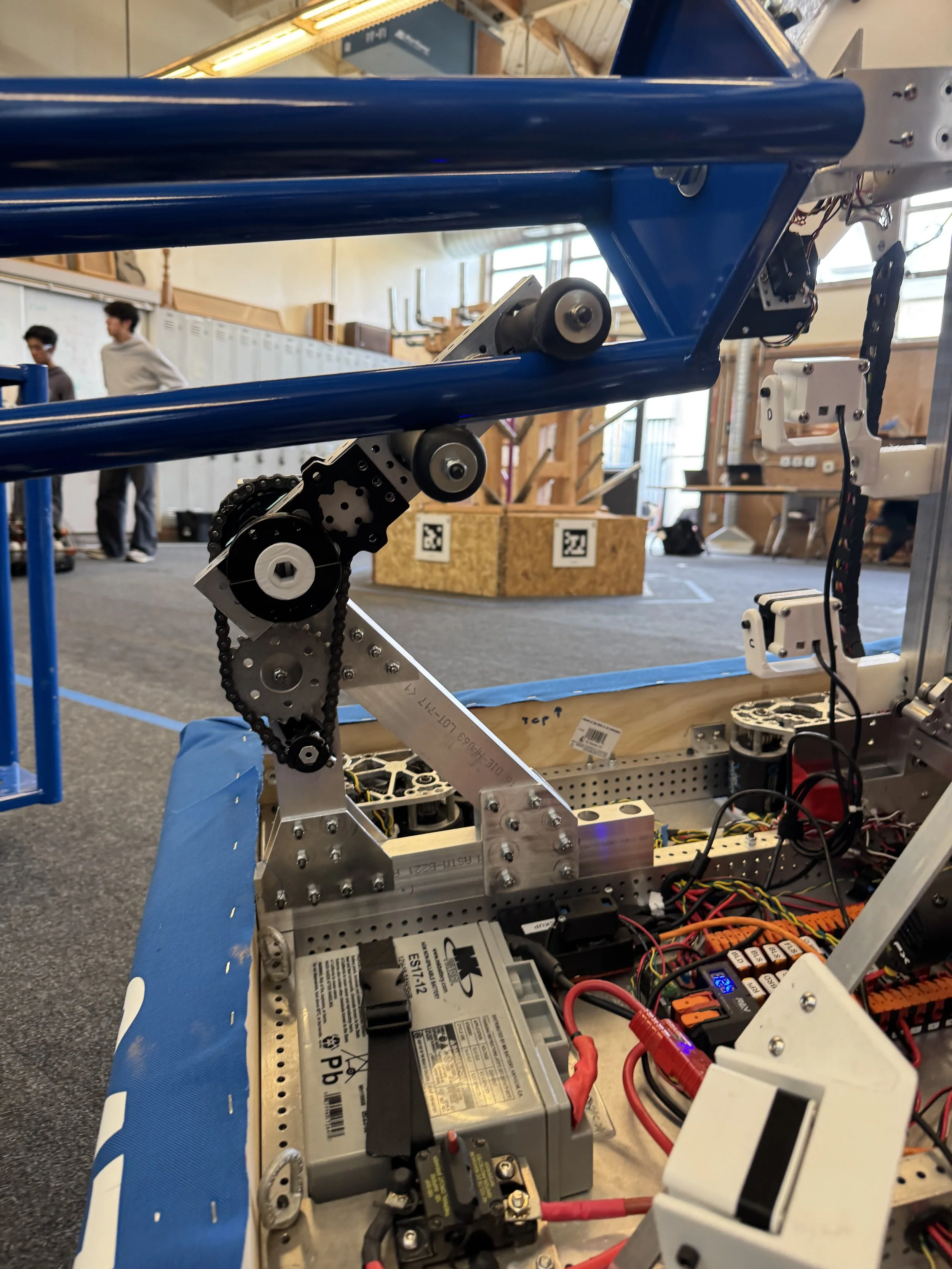

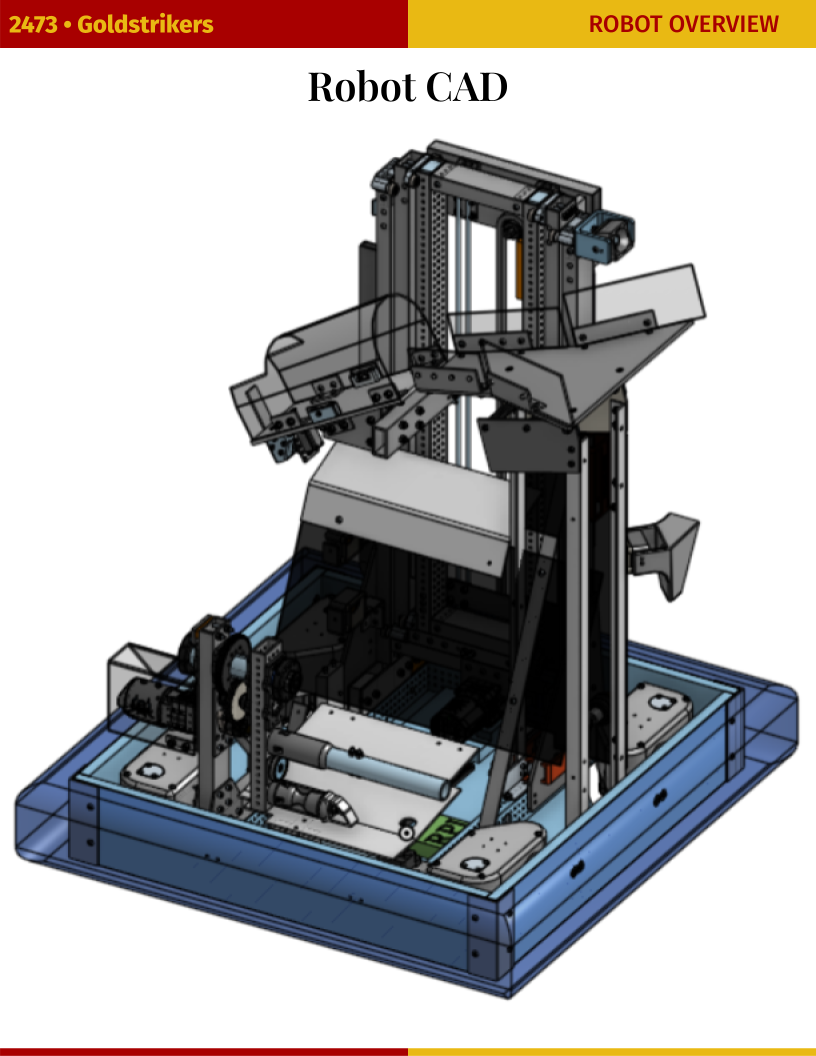

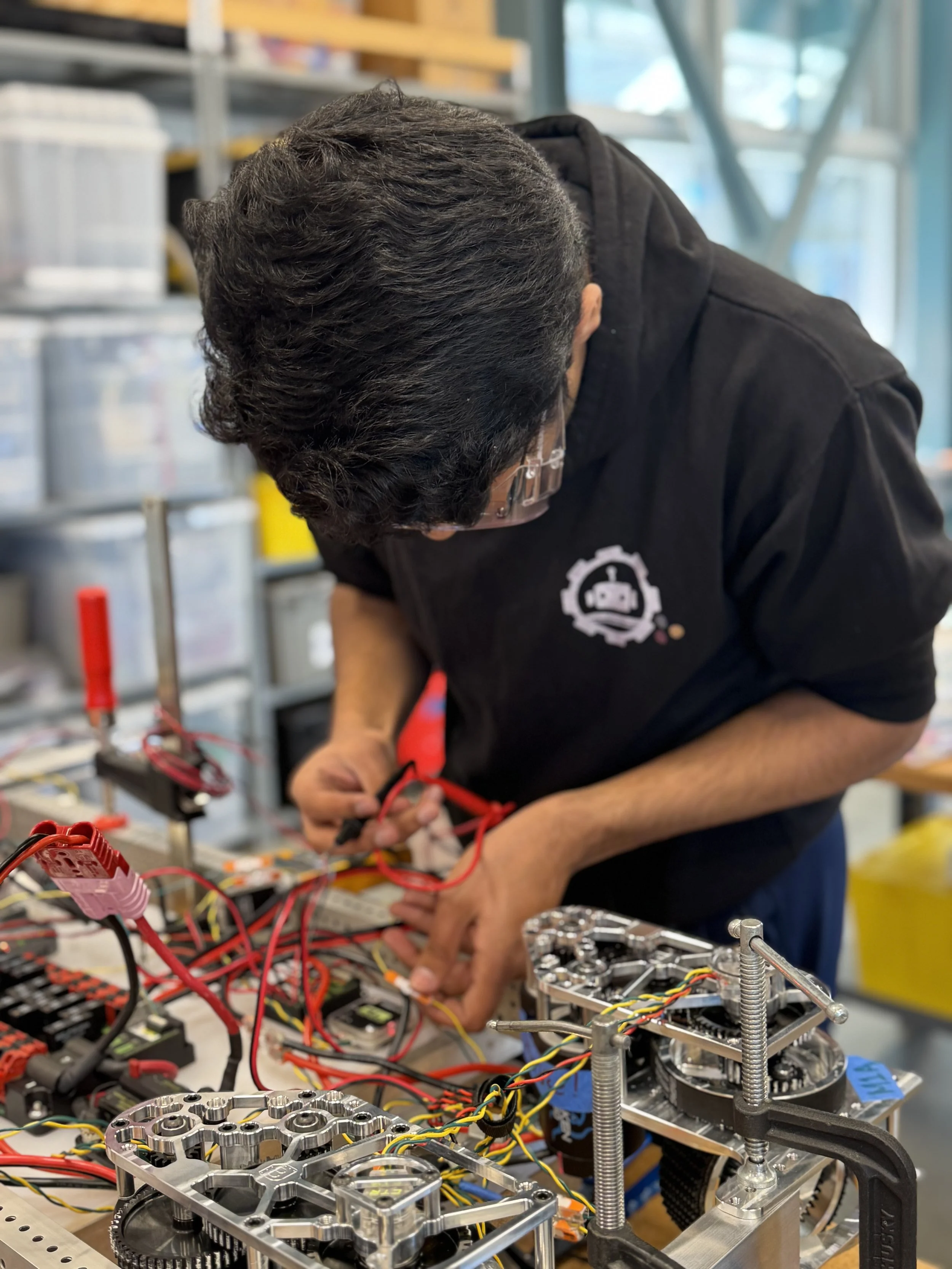

The hardware team focused on building a mechanically simple, robust robot optimized for high-throughput coral scoring and a deep climb. A major change this season was transitioning to MK4n swerve modules powered by Kraken motors, supported by thorough documentation of assembly, wiring, and CAN configuration. The robot features a two-stage cascade elevator designed early in the season to de-risk complexity, paired with a passive intake and servo-based outtake that minimizes weight and mechanical failure points. These choices allowed us to score reliably at L2–L4 while maintaining fast cycle times Engineering Portfolio_Notebook.

Equally important was how the team worked. Hardware was split into Design, Manufacturing, and Chassis subteams, enabling more students to contribute while developing specialized skills. Design focused on concept evaluation and CAD, Manufacturing handled fabrication using both manual and CNC equipment, and Chassis ensured drivetrain reliability and bumper construction. Decision matrices, rapid prototyping, and early standalone testing were used throughout the season to guide tradeoffs and reduce late-stage rework.

Software (SW)

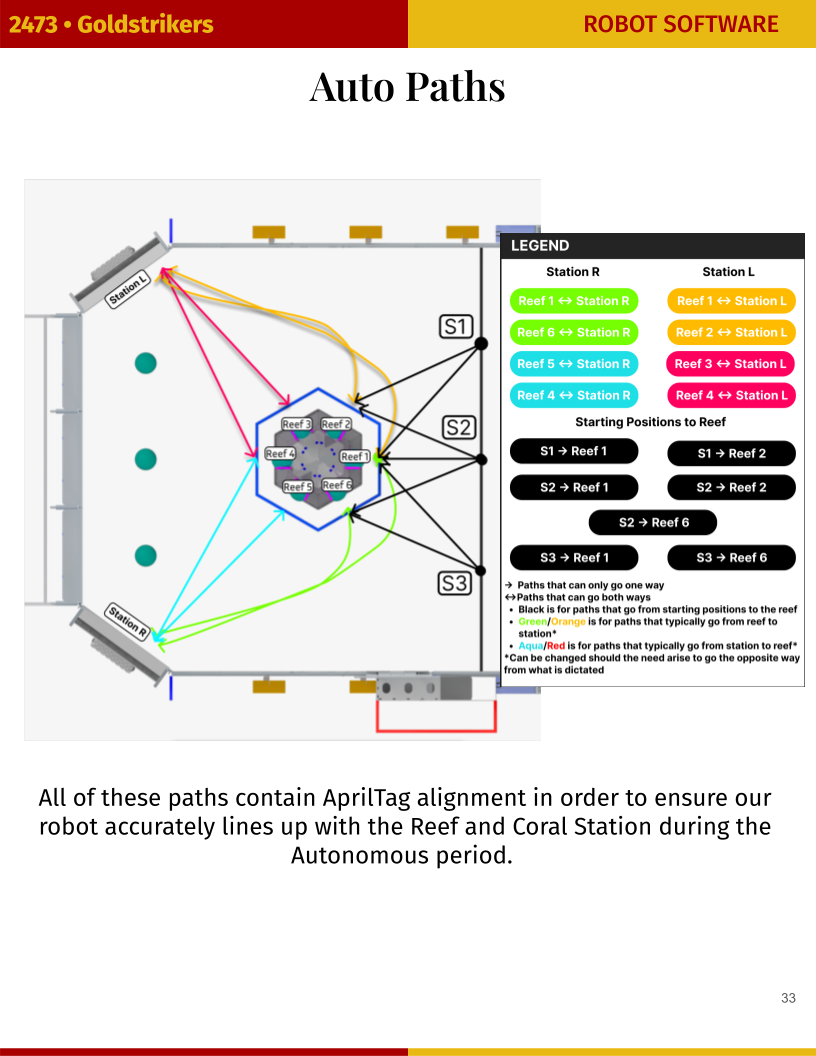

Software development centered on reliability, automation, and reducing driver workload. The team implemented a finite state machine (FSM) architecture across drivetrain and mechanisms, allowing complex actions such as alignment, scoring, and climbing to be executed consistently with minimal input. Autonomous and Tele-Op alignment relied heavily on AprilTag detection, enabling precise positioning at both the reef and coral station. This significantly improved cycle consistency and reduced alignment errors observed in previous seasons.

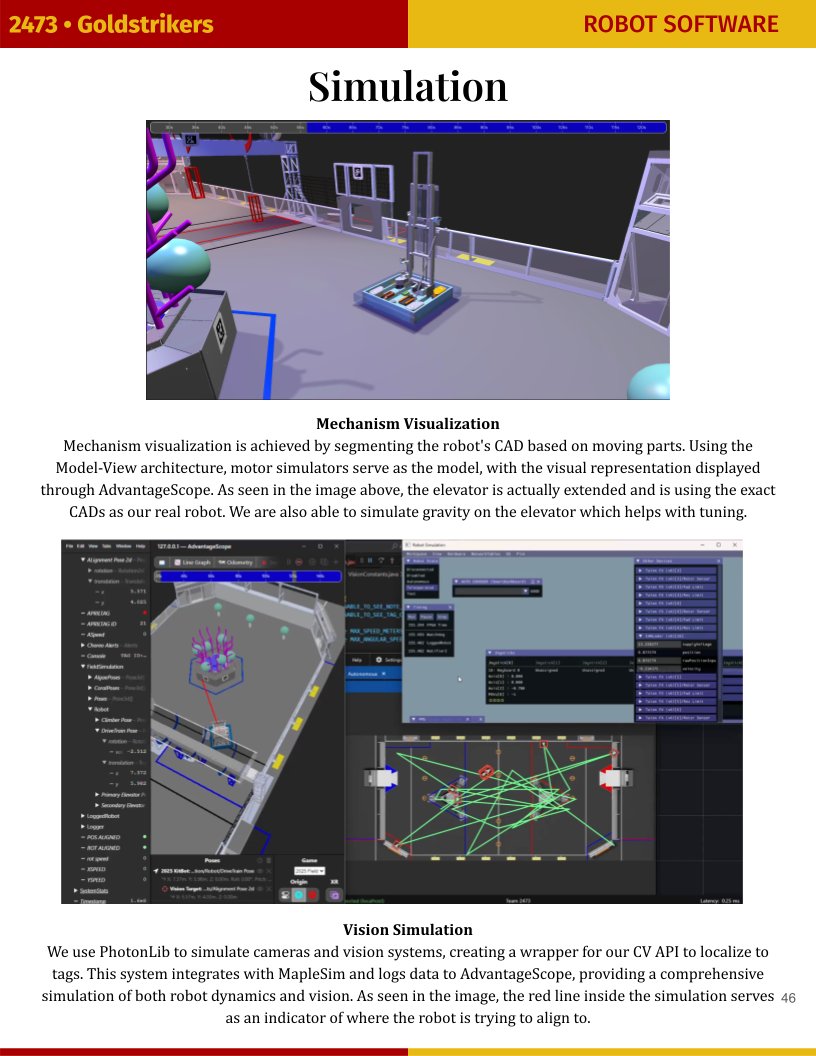

To support rapid iteration, the software team invested heavily in simulation. Using MapleSim, PhotonLib, and AdvantageKit, students were able to test drivetrain physics, vision systems, and mechanism logic without physical robot access. This approach saved significant testing time, enabled earlier debugging, and allowed drivers to practice in realistic virtual environments. The transition from PathPlanner to Choreo further improved autonomous efficiency by generating faster, more accurate trajectories based on real robot constraints.

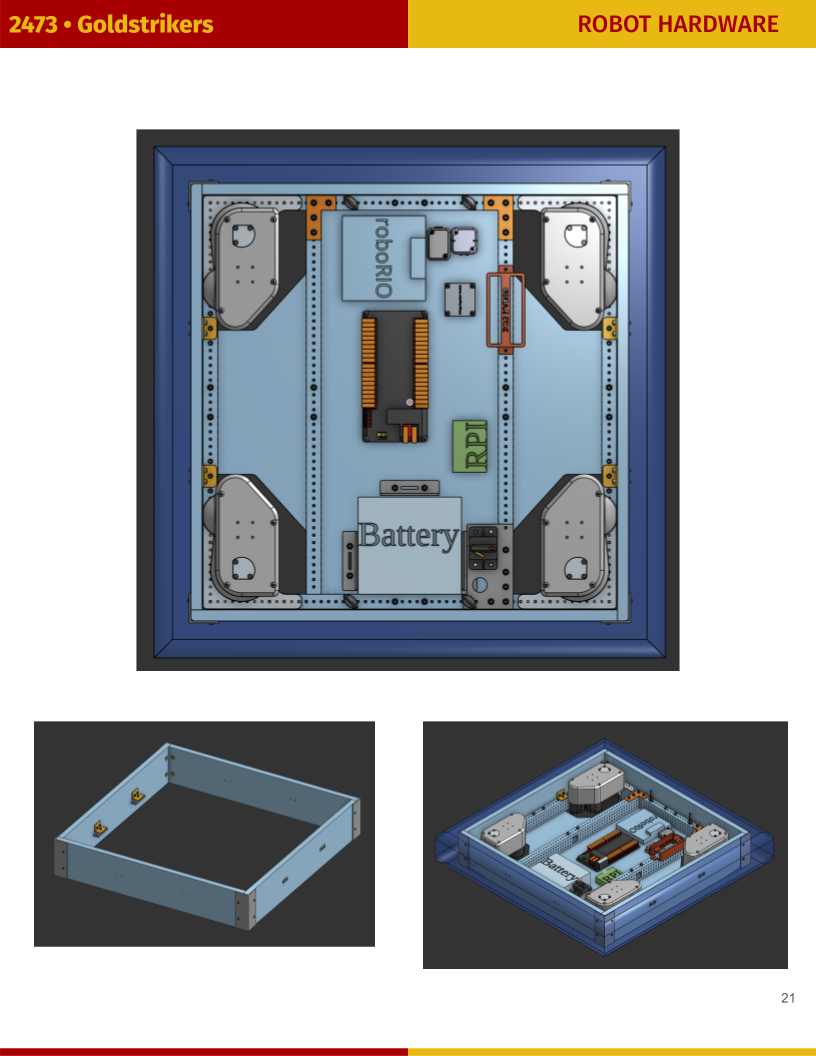

Electrical

The electrical subteam focused on reliability, documentation, and clean integration with the robot’s mechanical and software systems. This season marked a transition to CTRE-based hardware to support the MK4n drivetrain, requiring careful CAN bus planning, power distribution management, and sensor integration. The team emphasized wire management using structured routing and cable snakes to reduce strain and improve serviceability, especially on moving mechanisms like the elevator and outtake.

Beyond power and control, the electrical team expanded the robot’s feedback systems. Addressable LEDs were implemented to communicate robot state to drivers in real time, including alignment status, coral possession, autonomous mode, and climbing. These visual indicators improved match awareness and reduced driver error under pressure. Throughout the season, the subteam maintained detailed documentation to support debugging, repairs, and long-term knowledge transfer to newer students.